SOLID PRODUCT

FFS film Introduction

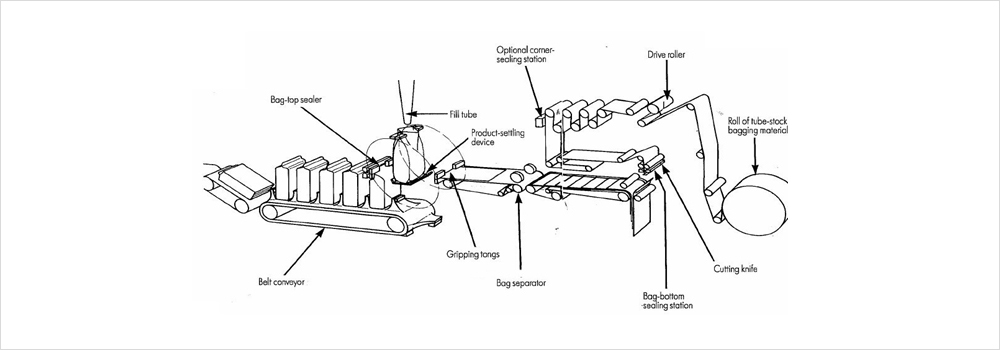

FFS is the abbreviation of form (automatic forming)-fill (online filing)-seal (heat sealing).

Three extruder production lines are adopted to manufature this product through molten co-extrusion, blow molding, electric corona, printing, folding, rolling and bag-making(bag cutting, heat sealing and packing can be conducted for FFS products as necessary).

This product can be applied to product packaging of resin, synthetic material, chemical fertilizer, mineral and powder.

Three extruder production lines are adopted to manufature this product through molten co-extrusion, blow molding, electric corona, printing, folding, rolling and bag-making(bag cutting, heat sealing and packing can be conducted for FFS products as necessary).

This product can be applied to product packaging of resin, synthetic material, chemical fertilizer, mineral and powder.

Specification

| Items | Unit | Technical Data |

|---|---|---|

| Loading weight | Kg | 10-30 |

| Thickness of film | mm | 0.12-0.22 |

| 2-sigma | % | < 4-8 |

| Width | mm | 450-750 |

| Gusset | mm | 45-110 |

| Printing | 4-color printing or customized | |

| Weight of bag | g | 90-200 |

FFS bag is made from LLDPE, HDPE, MLLDPE and other raw materials, can be recycling used, so it is a environment friendly packaging material, can be widely used in many sectors of the product packaging.

Features and Effective

Cost-Effectiveness

- High production outputs requesting high filling capacities reaching 2100 bags/hour

Film Customization

- Film Customization

Fully-Automated Packaging

- Forming, filling & sealing

Lead Time & Inventory

- High packing speed

- Short filling process production lead time

- Reduced inventory costs

Openability

- Proper film winding to avoid film blocking

- Designed film structure to secure easy material flow inside bags

Stackability

- High outer layer friction for better pallet shape & stability

Micro-Perforation

- For powder packaging to eliminate air entrapment after bag sealing

Printing

- Special ink with high resistance to UV radiation

- Mono or co-extruded form-fill-seal (FFS) bags for compounds, fertilizers, polymers, flakes, granules, powders and building materials.